Call Us

Call Us

+91-22-62700204 Email

Email

enquiry@calicometal.com

Call Us

Call Us Email

Email

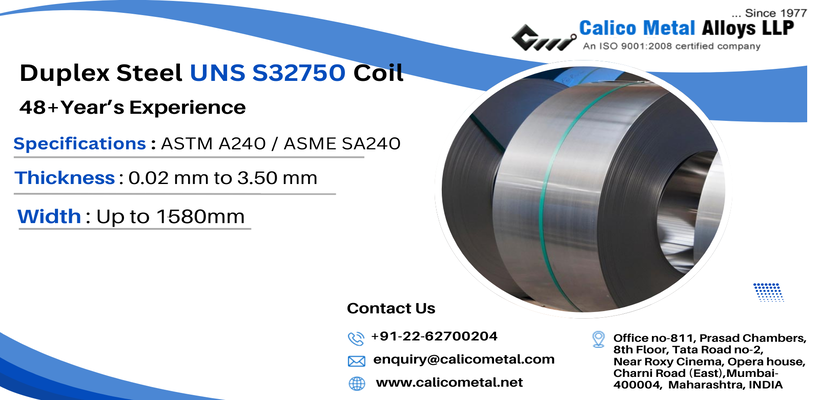

The ASTM A240 UNS S32750 coil has great properties as well as characteristics. These ASME SA240 UNS S32750 coil these features from their chemcialomosoiton. These ASTM A240 / ASME SA240 UNS S32750 coils are durable in nature. Along with being durable these Duplex Steel S32750 coils are lightweight. These ASTM A240 / ASME SA240 UNS S32750 coils are also dimensionally stable.

Because of all these features and attributes that these ASME SA240 UNS S32750 coils have, they are used in a large number of industrial applications. These applications include the oil and gas industries, power generations, chemical engineering. These ASTM A240 / ASME SA240 UNS S32750 coils are manufactured from high-quality raw materials. Therefore the Duplex Stainless Steel 2507 coils that are produced are also of excellent quality, and they also offer outstanding performance.

These ASTM A240 UNS S32750 coils also have to undergo a series of tests to test and enhance their quality. These Duplex S32750 coils are manufactured by considering the required rules as well as regulations. Therefore the ASTM A240 / ASME SA240 UNS S32750 coil that is produced has excellent performance and is of great quality.

Standard : ASTM A240 / ASME SA240

Width : 1000mm, 1219mm, 1500mm, 1800mm, 2000mm, 2500mm, 3000mm, 3500mm, etc

Thickness : 4mm-100mm

Length : 2000mm, 2440mm, 3000mm, 5800mm, 6000mm, etc

Surface Finish : 2B, 2D, BA, NO.1, NO.4, NO.8, 8K, hairline, sand blast, Brush, etching, Hot rolled coil (HR), Cold rolled coil (CR), SATIN (Met with Plastic Coated) etc

Hardness : Soft, Hard, Half Hard, Quarter Hard, Spring Hard etc.

Form : Coils, Foils, Rolls, Plain Coil, Shim Coil, Strip, Flats, Blank (Circle), Ring (Flange) etc.

| Element | Content (%) |

|---|---|

| Chromium, Cr | 24 – 26 |

| Nickel, Ni | 6 – 8 |

| Molybdenum, Mo | 3 – 5 |

| Manganese, Mn | 1.20 max |

| Silicon, Si | 0.80 max |

| Copper, Cu | 0.50 max |

| Nitrogen, N | 0.24 – 0.32 |

| Phosphorous, P | 0.035 max |

| Carbon, C | 0.030 max |

| Sulfur, S | 0.020 max |

| Iron, Fe | Balance |

| Properties | Metric | Imperial |

|---|---|---|

| Density | 7.8 g/cm3 | 0.281 lb/in3 |

| Melting point | 1350°C | 2460°F |

| SDSS F53 1/4 Hard coil | Werkstoff Nr. 1.4410 1/4 Hard coil |

| Werkstoff Nr. 1.4410 CR (Cold Rolled) coil | SDSS F53 Half Hard coil |

| ASTM A790 Super Duplex S32750 Quarter Hard coil |

ASTM A790 Super Duplex S32750 HR(Hot Rolled) coil

|

| Werkstoff Nr. 1.4410 Checkered coil | SDSS F53 Polished coil |

| UNS S32750 1/4 Hard coil | UNS S32750 Quarter Hard coil |

| Super Duplex 2507 Full Hard coil | SDSS F53 1/2 Hard coil |

| SDSS F53 Full Hard coil | SDSS F53 Galvanized coil |

| UNS S32750 Checkered coil | UNS S32750 Half Hard coil |

| UNS S32750 Full Hard coil | UNS S32750 HR(Hot Rolled) coil |

| ASTM A790 Super Duplex S32750 CR (Cold Rolled) coil | Werkstoff Nr. 1.4410 HR(Hot Rolled) coil |

| Super Duplex 2507 Polished coil | ASTM A790 Super Duplex S32750 1/4 Hard coil |

| Werkstoff Nr. 1.4410 Galvanized coil | ASTM A790 Super Duplex S32750 3/4 Hard coil |

| Werkstoff Nr. 1.4410 Full Hard coil | ASTM A790 Super Duplex S32750 Polished coil |

| SDSS F53 CR (Cold Rolled) coil | SDSS F53 HR(Hot Rolled) coil |

| UNS S32750 Polished coil | ASTM A790 Super Duplex S32750 Half Hard coil |

| Super Duplex 2507 HR(Hot Rolled) coil | Werkstoff Nr. 1.4410 Polished coil |

| UNS S32750 CR (Cold Rolled) coil | UNS S32750 1/2 Hard coil |

| Super Duplex 2507 Checkered coil | US $1,050.00 - $2,625.00 / Ton | Lightweight but strong – perfect for precise and delicate applications. |

| Super Duplex 2507 3/4 Hard coil | US $1,050.00 - $3,675.00 / Metric Ton | Designed for high-stress, high-temperature applications. |

| Werkstoff Nr. 1.4410 3/4 Hard coil | US $1,575.00 - $5,250.00 / Ton | Designed for use in boilers and pressure vessels under extreme conditions. |

| ASTM A790 Super Duplex S32750 Checkered coil | US $1,575.00 - $2,625.00 / Ton | Perfect for aesthetic applications with a polished, sleek surface. |

| ASTM A790 Super Duplex S32750 Galvanized coil | US $1,890.00 - $2,100.00 / Metric Ton | Excellent for intricate machining and fine finishes. |

| Super Duplex 2507 Quarter Hard coil | US $1,050.00 - $3,150.00 / Ton | Heavy-duty plates built for challenging construction tasks. |

| Werkstoff Nr. 1.4410 Half Hard coil | US $4,200.00 - $4,515.00 / Metric Ton | Durable, high-quality material for long-term heavy-duty usage. |

| Super Duplex 2507 CR (Cold Rolled) coil | US $1,050.00 - $3,570.00 / Metric Ton | Excellent for pressure vessels, heat exchangers, and other industrial uses. |

| UNS S32750 3/4 Hard coil | US $2.10 - $5.25 / Kilogram | Strong, reliable, and available in various thicknesses for tailored use. |

| Super Duplex 2507 1/4 Hard coil | US $1,050.00 - $2,625.00 / Ton | Ideal for industrial applications requiring strength & durability. |

| Super Duplex 2507 Galvanized coil | US $2,992.50 - $3,150.00 / Ton | High-performance material for critical infrastructure. |

| ASTM A790 Super Duplex S32750 1/2 Hard coil | US $4,200.00 - $4,725.00 / Metric Ton | Premium grade for superior mechanical properties. |

| Super Duplex 2507 Half Hard coil | US $2.10 - $5.25 / Kilogram | Reliable for welding and forming applications. |

| SDSS F53 3/4 Hard coil | US $840.00 - $3,150.00 / Ton | Hot deal – available in a range of thicknesses for different industries. |

| Werkstoff Nr. 1.4410 Quarter Hard coil | US $2,624.00 - $2,729.00 / Ton | High-strength, ideal for structural integrity in demanding environments. |

| Super Duplex 2507 1/2 Hard coil | US $933,332.40 / Piece | Custom, specialized plates made to order for unique projects. |

| UNS S32750 Galvanized coil | US $1.05 - $2.94 / Kilogram | Ideal for the shipbuilding industry with exceptional resilience. |

| SDSS F53 Quarter Hard coil | US $1,050.00 - $6,090.00 / Metric Ton | Suitable for both light and heavy-duty applications. |

| ASTM A790 Super Duplex S32750 Full Hard coil | US $2.63 - $10.50 / Kilogram | Versatile, corrosion-resistant, and perfect for a variety of projects. |

| SDSS F53 Checkered coil | US $840.00 - $5,124.00 / Ton | Prized for corrosion resistance and toughness in extreme conditions. |

Calico Metal Alloys LLP exports their products to countries like UAE, Bahrain, Italy, Indonesia, Malaysia, United States, Mexico, Chine, Brazil, Peru, Nigeria, Kuwait, Jordan, Dubai, Thailand (Bangkok), Germany, UK, Canada, Turkey, Australia, New Zealand, Sri Lanka, Vietnam, South Africa, Kazakhstan & Saudi Arabia.